Custom control systems development—that’s where Devion’s story began over 20 years ago. Today, it has made us specialists in system integration. With a PLC as the “brain,” a user-friendly SCADA interface, and an MES as a dynamic production system, the possibilities are virtually endless. From revamping a single machine to controlling an entire production line or managing a fully automated warehouse.

System integration as the foundation of your production

From detailed design and software coding to programming and machine construction: at Devion, you can count on expert custom-made solutions from start to finish. This is how we deliver on our promise of a safer, faster, more precise, and worry-free production process.

"Where Devion’s story began is where we still lead today."

MES, SCADA and PLC:

Three Key Pillars of Our Approach

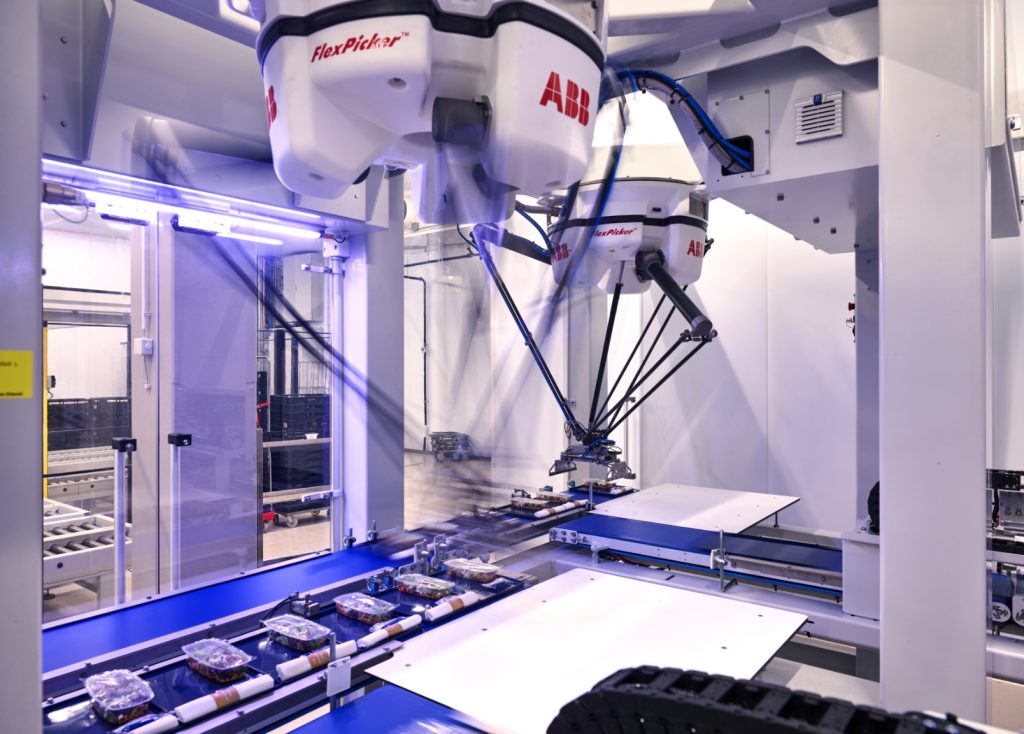

The core of your automation process? It’s the MES, SCADA, and PLC programming. Our software specialists write customized programs tailored to your needs, requirements, and challenges. This way, we create a “brain” and all the necessary “senses” (such as sensors) to perfectly synchronize your machines, robots, and automated transport systems.

Proces integration

Optimal collaboration between all components is the key to successful system integration. Process integration forms the primary building block of this.

Motion-systems

These motors, equipped with pneumatic cylinders and feedback systems, initiate movements that are precise, fast, and efficient—while exchanging data to coordinate seamlessly with each other.

End-to-end control of production lines

From frying chips to blending fruit yogurts: through system integration, Devion makes production lines fully automated and highly efficient from start to finish.

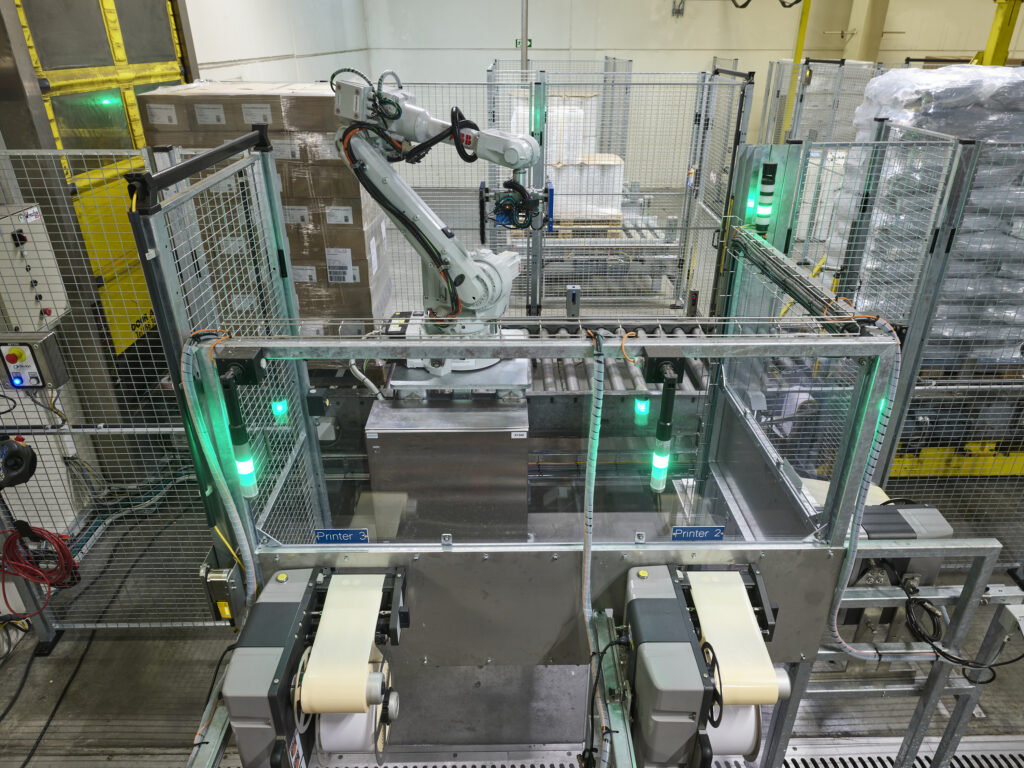

Warehousing

Developing the optimal control system for cranes and robots in large automated warehouses—using the ideal commands for fast operation and efficient order processing.

Machine revamps

Equipping existing, often outdated, machines with robust mechanics with a new control system—featuring smarter operation and compliance with current safety standards.

ERP-link

A connection between the planning software (ERP) and the production environment, enabling smooth order processing. The right programs are automatically activated, inventories monitored, and more.

OEE-reporting

Automatic reporting on the actual speed of a production line, the difference from the theoretical speed, and the underlying causes—designed to identify bottlenecks and drive improvements.

Looking for an expert partner in system integration?